Mann Engineering Ltd

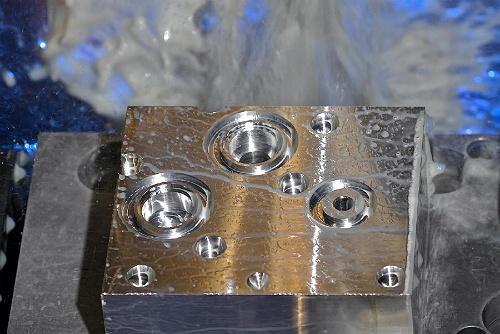

Specialising in the supply of Complex Precision Mill/Turn Components

| About | Mann Engineering specializes in the accredited supply of Complex Precision Mill/Turn Components from 3mm to 120mm Diameter, produced on State of the Art Multi-Axis Lathes, in Low to Medium volume. We also offer 3 & 4 axis milling and low level component assembly & testing. |

| Sectors | Aerospace, Oil & Gas, Electrical Distribution, Valve & Actuator, Dairy, Medical Device, Hydraulic, Fluids, Steam Tech & Marine |

| Vision | Continue to build long term relationships with our customers, offering a one-stop shop, offering turning & milling and to also incorporate low level testing & assembly. |

| History | Mann Engineering has grown to a 10,000 sq. ft. facility situated on 1 acre privately owned site. Turnover €2.2m+, employing 25 personnel. AS9100 Rev D & ISO9001 accredited & members of ADS. |

| Founded | 1993 |

Mann Engineering Ltd

Mill/Turn

| Type | Number | Details |

|---|---|---|

| Miyano ABX 51 Fixed Head 10 Axis Lathe. | 3 | Bar feed Capacity Dia. 3.0 – 50.8 mm (Billet up to Dia 200mm) |

| Miyano ABX 64 Fixed Head 10 Axis Lathe. | 2 | Bar Feed Capacity Dia. 3.0 – 63.5 mm (Billet up to Dia 200mm) |

| Tornos Swiss ST26, 8 axis sliding head lathe | 1 | Bar Feed Capacity Dia 3.0 – 25.4mm |

| Tornos Delta 38, 8 axis sliding head lathe | 1 | Bar Feed Capacity Dia 3.0 – 38mm |

| Cincinnati 150 Hawk Fixed Head 2 Axis Lathe. | 2 | Capacity up Dia. 50.8 m |

| Style Prototyping. | 1 | Capacity up Dia. 50.8 mm |

Machining Centres

| Type | Number | Details |

|---|---|---|

| Lagun Machine Centre with universal head, 3 axis | 1 | X = 3000 mm, Y = 1000 mm, Z = 800 mm |

| Kitamura Drill Centre, 3 axis | 1 | X = 500mm, Y = 350mm, Z = 300mm |

| Kitamura Drill Centre, 4 axis | 1 | X = 500mm, Y = 350mm, Z = 300mm |

| Dugard Eagle Machining Centre | – | – |

Low Level Assembly

| Details |

|---|

| Low Level Component Assembly |

| Component Testing |

| Pressure Testing |

Treatments

| Mann Engineering work closely with both local & national Treatment/Finishing companies offering; |

|---|

| Anodizing - Various Colours |

| Hard Anodizing |

| Zinc Plating |

| Tin Plating |

| Molycoating |

| Black Oxide |

| Electro-polishing |

| Powder Coating |

Quality

| Details |

|---|

| AS9100 Rev D accredited |

| ISO9001 accredited |

| General inspection equipment includes; |

| Zeiss Duramax CMM |

| Telesis EV15 Laser Marker |

| Starret Shadow Graph |

| Rockwell Hardness Tester |

Ancillary

| Details |

|---|

| CNC Bomer Saw |

| Beadblasting Booth |

| Durr Ultrasonic Parts Cleaner |

Mill/Turn

| Type | Number | Details |

|---|---|---|

| Miyano ABX 51 Fixed Head 10 Axis Lathe. | 3 | Bar feed Capacity Dia. 3.0 – 50.8 mm (Billet up to Dia 200mm) |

| Miyano ABX 64 Fixed Head 10 Axis Lathe. | 2 | Bar Feed Capacity Dia. 3.0 – 63.5 mm (Billet up to Dia 200mm) |

| Tornos Swiss ST26, 8 axis sliding head lathe | 1 | Bar Feed Capacity Dia 3.0 – 25.4mm |

| Tornos Delta 38, 8 axis sliding head lathe | 1 | Bar Feed Capacity Dia 3.0 – 38mm |

| Cincinnati 150 Hawk Fixed Head 2 Axis Lathe. | 2 | Capacity up Dia. 50.8 m |

| Style Prototyping. | 1 | Capacity up Dia. 50.8 mm |

Machining Centres

| Type | Number | Details |

|---|---|---|

| Lagun Machine Centre with universal head, 3 axis | 1 | X = 3000 mm, Y = 1000 mm, Z = 800 mm |

| Kitamura Drill Centre, 3 axis | 1 | X = 500mm, Y = 350mm, Z = 300mm |

| Kitamura Drill Centre, 4 axis | 1 | X = 500mm, Y = 350mm, Z = 300mm |

| Dugard Eagle Machining Centre | – | – |

Ancillary

| Details |

|---|

| CNC Bomer Saw |

| Beadblasting Booth |

| Durr Ultrasonic Parts Cleaner |

Quality

| Details |

|---|

| AS9100 Rev D accredited |

| ISO9001 accredited |

| General inspection equipment includes; |

| Zeiss Duramax CMM |

| Telesis EV15 Laser Marker |

| Starret Shadow Graph |

| Rockwell Hardness Tester |

Want to become a member?

If you want to join the Emerald Aero Group cluster or would like a more information click below!